平頂鏈結(jié)構(gòu)十分簡單,僅一塊兩側(cè)帶鉸圈的鏈板與一要銷軸。兩側(cè)鉸圈的一側(cè)與銷軸固定聯(lián)結(jié),稱為固定鉸圈。另一側(cè)處在里檔的鉸圈與銷軸滾動(dòng)聯(lián)結(jié),稱為活動(dòng)鉸圈?;顒?dòng)鉸圈與與銷軸構(gòu)成了平頂鏈的鉸鏈。因平頂鏈?zhǔn)褂脮r(shí)經(jīng)常要與液態(tài)物質(zhì)接觸,所以鏈板材料用不銹鋼制造居多,當(dāng)然也有用工程塑料來制造的。鋼制平頂鏈的鉸圈是卷制而成的,所以鉸圈是有縫的,圓度不易保證。載荷大時(shí)還會(huì)被拉開,是一處薄弱環(huán)節(jié)。隨著工裝塑料的發(fā)展,工程塑料平頂鏈也憶開發(fā)出來。由于工程塑料的平頂鏈鏈板是澆鑄成型的,所以鏈板的結(jié)構(gòu)可以按需要采用較為復(fù)雜的形狀。因?yàn)殒湴迳隙加屑訌?qiáng)肋,所以能提高鏈條的強(qiáng)度。雙彎加強(qiáng)肋鉸鄭式直行平頂鏈的強(qiáng)度并不比鋼制的簡單鉸卷式平頂鏈低。

Features:

Flat-top chain structure is very simple, only on both sides of a piece with hinged ring chain plate with a pin.On both sides of the hinge on one side of the circle and the pin shaft fixed connection, known as the fixed hinge.In the other side is archives circle of hinged with the rolling pin shaft coupling, called active hinge.Activity hinge circle and form the hinge of the flat chain with pin.Because of flat chain when using often want to contact with the liquid material, so the chain plate made of stainless steel material, of course also useful to manufacturing engineering plastics.Steel flat chain circle of hinge is developed, and so the hinge circle is a seam, roundness is not easy to guarantee.The load will be opened and is a weak link.With the development of plastic tooling, engineering plastic flat chain also have developed.As a result of the engineering plastic flat chain chain plate is cast molding, so the structure of the chain plate can according to need to adopt more complex shapes.Because the chain board has a stiffening rib, so can improve the strength of the chain.Double curved stiffened hinge zheng went flat top the strength of the chain is not lower than the simple hinge volume type flat steel chain.

Features:

Flat-top chain structure is very simple, only on both sides of a piece with hinged ring chain plate with a pin.On both sides of the hinge on one side of the circle and the pin shaft fixed connection, known as the fixed hinge.In the other side is archives circle of hinged with the rolling pin shaft coupling, called active hinge.Activity hinge circle and form the hinge of the flat chain with pin.Because of flat chain when using often want to contact with the liquid material, so the chain plate made of stainless steel material, of course also useful to manufacturing engineering plastics.Steel flat chain circle of hinge is developed, and so the hinge circle is a seam, roundness is not easy to guarantee.The load will be opened and is a weak link.With the development of plastic tooling, engineering plastic flat chain also have developed.As a result of the engineering plastic flat chain chain plate is cast molding, so the structure of the chain plate can according to need to adopt more complex shapes.Because the chain board has a stiffening rib, so can improve the strength of the chain.Double curved stiffened hinge zheng went flat top the strength of the chain is not lower than the simple hinge volume type flat steel chain.

應(yīng)用

平頂鏈具有結(jié)構(gòu)簡單、重量輕、制造和維修方便的優(yōu)點(diǎn)。平頂鏈的頂板為輸送物料提供了一定寬度的水平承載面。頂板寬度按輸送物料的要求確定。鏈條與鏈輪嚙合時(shí),鉸圈本身就是與鏈輪嚙合的部位。因平行排列的頂板鏈兩側(cè)間隙小,所以,只能作直線移動(dòng)。就用平頂鏈時(shí)正確定裝十分重要。廣泛應(yīng)用于直行板鏈輸送機(jī)的設(shè)計(jì)。多條并列的鏈板輸送機(jī)可用采用網(wǎng)帶輸送機(jī)來代替。

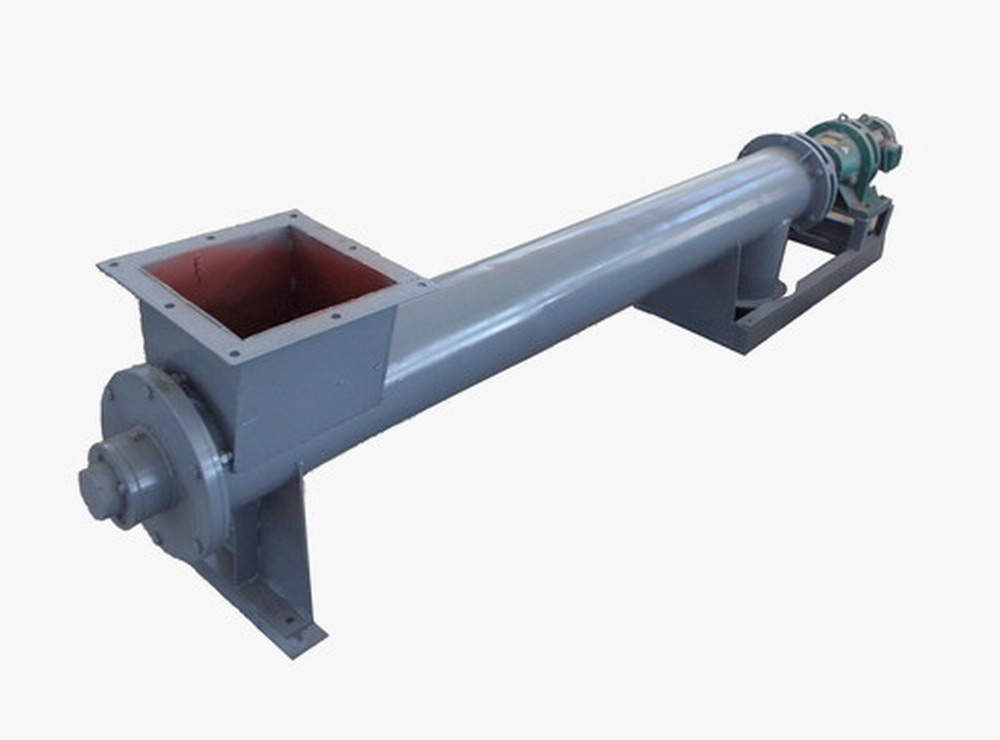

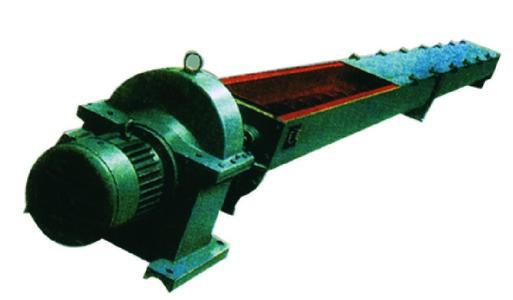

板鏈輸送機(jī)適用于形狀不規(guī)則物品的重載輸送。鏈條選用空心大輥?zhàn)訋Ц郊湕l,在兩側(cè)同步鏈條的附件上用板狀構(gòu)件連接使輸送方向形成連續(xù)的平板,因而運(yùn)行平穩(wěn)。該機(jī)與鏈?zhǔn)交蜉佂草斔蜋C(jī)配合使用可實(shí)現(xiàn)轉(zhuǎn)角輸送。

Applications:

Flat-top chain has a simple structure, the advantages of light weight, easy to manufacture and maintenance.Flat-top chain the roof for conveying material width of the level of the bearing surfaces.Top plate width is determined according to the requirement of the conveying material.Chain and sprocket meshing, hinged ring itself is one of the sprocket meshing area.For parallel arrangement of roof chain side clearance is small, so, can only make straight line movement.With flat-top chain is determined when the loading is very important.Widely used in straight andante chain conveyor design.Multiple coordinate chain conveyor mesh belt conveyor is used to replace available.

Plate chain conveyor is suitable for the irregular shape goods overload transportation.Chain choose hollow roller chain with attachments, with plate component synchronous chain accessories on both sides the conveying direction connection form the continuous tablet, thus smooth operation.This machine used with chain or roller conveyor can realize Angle conveyor.

Applications:

Flat-top chain has a simple structure, the advantages of light weight, easy to manufacture and maintenance.Flat-top chain the roof for conveying material width of the level of the bearing surfaces.Top plate width is determined according to the requirement of the conveying material.Chain and sprocket meshing, hinged ring itself is one of the sprocket meshing area.For parallel arrangement of roof chain side clearance is small, so, can only make straight line movement.With flat-top chain is determined when the loading is very important.Widely used in straight andante chain conveyor design.Multiple coordinate chain conveyor mesh belt conveyor is used to replace available.

Plate chain conveyor is suitable for the irregular shape goods overload transportation.Chain choose hollow roller chain with attachments, with plate component synchronous chain accessories on both sides the conveying direction connection form the continuous tablet, thus smooth operation.This machine used with chain or roller conveyor can realize Angle conveyor.

材質(zhì)

碳鋼、不銹鋼、熱塑鏈,根據(jù)產(chǎn)品的需要可選取不同寬度、不同形狀的頂板來完成直線、轉(zhuǎn)彎、升降等要求。

The material

Carbon steel, stainless steel, thermoplastic chain, according to the need of the product can choose different width, different shapes of roof to complete a straight line, turning and lifting requirements.

The material

Carbon steel, stainless steel, thermoplastic chain, according to the need of the product can choose different width, different shapes of roof to complete a straight line, turning and lifting requirements.

分類

因控制方式的不同,可分為連續(xù)運(yùn)行式和間歇運(yùn)行式。

classification

Because of the different methods of control, can be divided into continuous operation and intermittent operation.

classification

Because of the different methods of control, can be divided into continuous operation and intermittent operation.

主要技術(shù)參數(shù):

鏈條節(jié)距:25.4mm~203.2mm

板鏈輸送機(jī)寬度:200mm~800mm

(寬度超過800mm時(shí),可使用雙板鏈結(jié)構(gòu))

輸送速度:0.4m~15m/Min

輸送物品最大重量:800kg/m2

金屬板鏈工作環(huán)境溫度:-20℃~+120℃

The main technical parameters:

The chain pitch: 25.4 mm to 203.2 mm

Plate chain conveyor width: 200 mm to 800 mm

When more than 800 mm (width, can use the double plate chain structure)

Conveyor speed: 0.4 m to 15 m/Min

Delivery goods maximum weight: 800 kg/m2

Metal plate chain working environment temperature: - 20 ℃ ~ + 120 ℃

The main technical parameters:

The chain pitch: 25.4 mm to 203.2 mm

Plate chain conveyor width: 200 mm to 800 mm

When more than 800 mm (width, can use the double plate chain structure)

Conveyor speed: 0.4 m to 15 m/Min

Delivery goods maximum weight: 800 kg/m2

Metal plate chain working environment temperature: - 20 ℃ ~ + 120 ℃

定制板鏈輸送機(jī)請請確認(rèn)以下技術(shù)參數(shù):

1.輸送物料的單件重量,物料的規(guī)格大小。

2.使用環(huán)境,環(huán)境溫度。

3.輸送速度(米/分鐘)。

4.安裝場地要求,布置形式。

5.是否需要調(diào)速。

我公司可根據(jù)客戶要求重新設(shè)計(jì)。

Custom plate chain conveyor, please confirm the following parameters:

1. Conveying material piece weight, material of the specifications of the size.

2. Using the environment, the environment temperature.

3. Delivery speed (m/min).

4. Installation site requirement, decorate a form.

5. Whether you need speed.

Our company can according to customer requirements to design.

Custom plate chain conveyor, please confirm the following parameters:

1. Conveying material piece weight, material of the specifications of the size.

2. Using the environment, the environment temperature.

3. Delivery speed (m/min).

4. Installation site requirement, decorate a form.

5. Whether you need speed.

Our company can according to customer requirements to design.